In the realm of protective coatings, PVC dip coating has emerged as a leading choice for numerous industries, owing to its versatility and durability. According to a report by MarketsandMarkets, the global market for polymer coatings, which includes PVC dip coating, is projected to reach approximately $14.99 billion by 2025, growing at a CAGR of 5.7% from 2020. This growth highlights the increasing demand for efficient coating solutions that not only enhance product longevity but also improve safety and aesthetic appeal. PVC dip coating provides a seamless and robust finish that is resistant to abrasion, chemicals, and UV exposure, making it ideal for applications ranging from automotive parts to consumer goods. As manufacturers seek innovative ways to elevate their products' performance, mastering PVC dip coating techniques can lead to sustainable advantages in product protection and market competitiveness.

When embarking on the journey of PVC dip coating, having the right tools and materials is crucial for achieving a flawless finish. First and foremost, select high-quality PVC dip coating solutions that are compatible with the surfaces you'll be working on. Ensure you have gloves, goggles, and a respirator for safety, as the process may involve fumes and chemicals. Additionally, a suitable dipping tank is essential for deep immersion; consider a container that provides enough depth for the items you plan to coat.

Tips: Always prepare your surfaces by cleaning them thoroughly and removing any existing coatings or contaminants. This step will enhance the adhesion of the PVC coating, leading to better overall protection.

For application, consider using a heat gun to pre-warm your items before dipping. This practice can help the PVC adhere better and create a smoother finish. Don't forget essential materials such as mixing sticks, brushes for touch-ups, and a drying rack to allow your coated items to cure properly without any contact marks.

| Tool/Material | Purpose | Specifications | Quantity |

|---|---|---|---|

| PVC Dipping Compound | Primary coating material for protection | Temperature resistant, non-toxic | 2 kg |

| Heating Element | Heat the PVC compound for better adhesion | Adjustable temperature control | 1 |

| Dipping Basket | Holds items while dipping into the coating | Stainless steel, rust-resistant | 1 |

| Ventilation System | Removes fumes during dipping | Powerful suction fans | 1 |

| Safety Gear | Protects user from exposure | Gloves, goggles, mask | 1 set |

Preparing items for PVC dip coating is essential for achieving optimal product protection. The first step involves thorough cleaning to remove any dirt, grease, or residue. According to a report by the Coating Research Institute, clean surfaces can improve adhesion by up to 75%. This step may involve using solvents, detergents, or abrasive materials, depending on the item's initial condition. After cleaning, ensure that the item is completely dry; moisture can compromise the coating's adhesion and durability.

Once the item is clean and dry, the next step is to apply a primer, especially for metal objects. Primers enhance adhesion and can significantly extend the service life of the coating. The Coating Industry Association states that using a primer can increase the lifespan of coatings by an estimated 30%. After applying the primer, allow it to cure properly before proceeding to the actual dip coating process.

**Tips**: Always wear protective gear, such as gloves and masks, to prevent exposure to hazardous materials during preparation. Additionally, consider practicing your dipping technique on a test item to familiarize yourself with the process and achieve a uniform coating on your final product. Lastly, ensure your dipping setup is in a well-ventilated area to allow for proper fume dissipation.

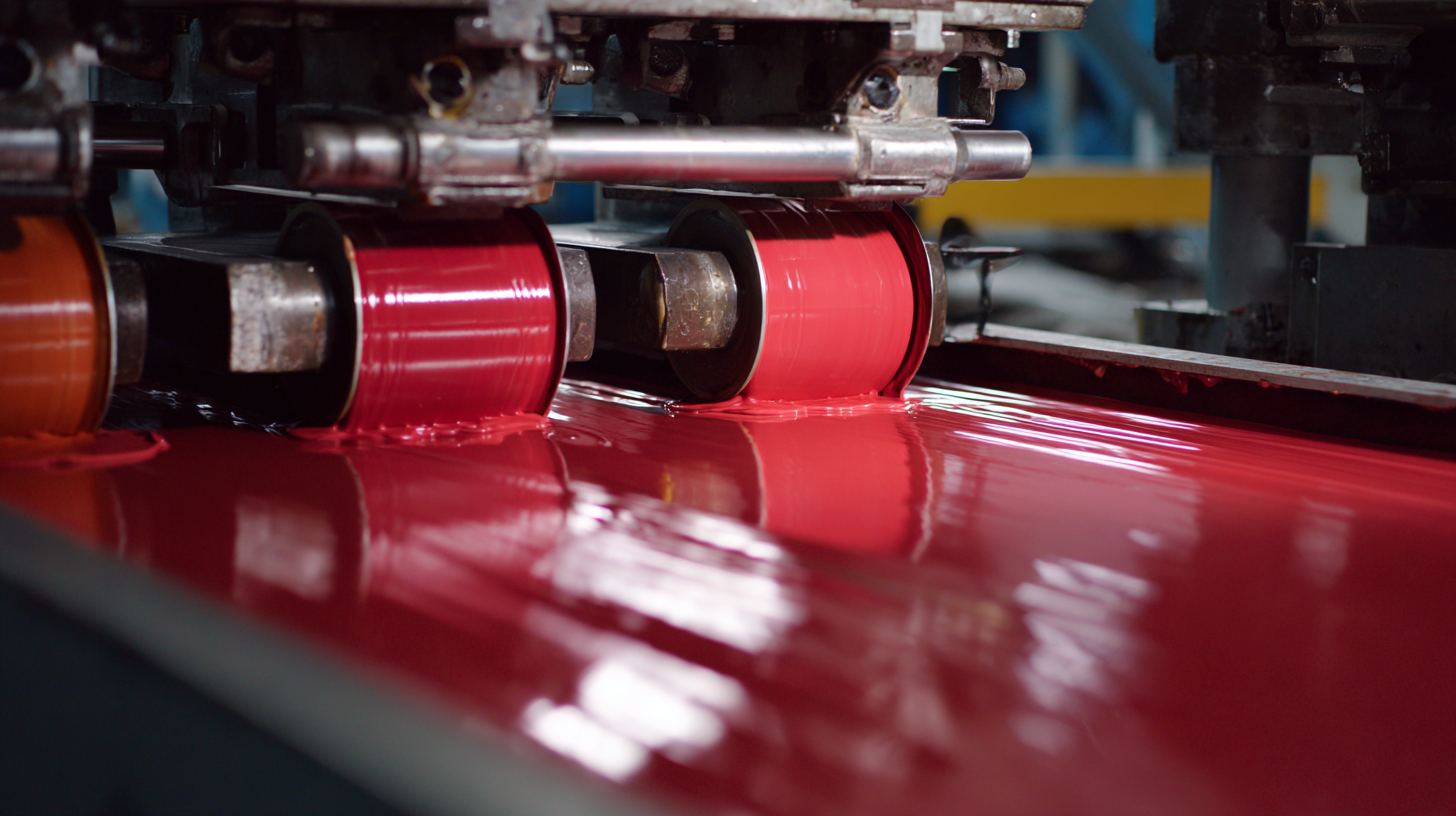

When it comes to PVC dip coating, achieving a smooth and even coating finish is paramount for the protection and longevity of products. According to a report from Smithers Pira, the global demand for PVC coatings is expected to reach 1.4 million tons by 2025, illustrating a growing recognition of its effectiveness in barrier protection. To master the dip coating technique, one must focus on factors such as temperature control, immersion time, and post-dipping curing.

Temperature is crucial; maintaining an optimal dipping temperature between 180°F and 210°F can significantly enhance the fluidity of the PVC, allowing it to flow smoothly over the substrate. Additionally, the time the product is submerged in the PVC material directly influences the thickness of the coating. A dip time of approximately 30 seconds to 2 minutes is recommended, depending on the desired thickness. Furthermore, allowing for proper curing time post-dipping ensures that any imperfections such as drips or pooling are minimized, leading to a consistent finish. By adhering to these techniques, manufacturers can achieve a coating that not only looks good but also provides long-lasting protection against environmental factors.

Troubleshooting common issues in PVC dip coating is essential for achieving a high-quality finish and ensuring the longevity of coated products. One significant challenge encountered during the dip coating process is the occurrence of pinholes or bubbles on the surface. According to a report by the American Coatings Association, proper temperature control during both the preheating and curing phases can reduce the incidence of these unwanted defects. A recommended practice is to maintain a consistent ambient temperature, ideally between 60°F and 80°F, to optimize the flow of PVC and minimize imperfections.

Another frequent issue is inadequate adhesion, which can arise from improper surface preparation. Industry studies indicate that more than 30% of coating failures are attributed to insufficient cleaning before dipping. It is crucial to thoroughly clean and, if necessary, roughen the surface of the substrate to promote better bonding with the PVC. After cleaning, ensure that the surface is free from any contaminants such as oil or dust.

Tips: Always test a small batch to identify any potential issues before proceeding with a larger run. Regular maintenance of the dipping equipment is also key; ensure that the dip tanks are cleaned periodically to prevent contamination of the PVC. Finally, conducting regular quality checks on the coated products can help catch and rectify problems early, ensuring the final product meets the desired standards of protection and appearance.

Curing and maintaining PVC coated products is crucial for achieving long-lasting durability and optimal performance. The curing process involves allowing the PVC coating to set properly, which enhances its adhesion and resistance to wear and tear. Ensure that you follow the manufacturer's guidelines regarding curing times and temperatures. Typically, a controlled environment with consistent temperature and humidity levels will yield the best results.

Tips: Always inspect the coated items after curing. Look for any inconsistencies or defects in the coating, as these may compromise the product's integrity. Additionally, consider implementing a scheduled maintenance routine to clean and repair the coated surfaces regularly. This helps to remove debris and prevent buildup that could damage the coating over time.

When it comes to the maintenance of PVC coated products, avoid harsh chemicals that might degrade the coating. Instead, use gentle cleaning agents and soft cloths to maintain the surface. Regularly check for signs of wear or damage, and address these issues promptly to prolong the life of the coated product. Proper care and attention to detail during both the curing and maintenance stages will ensure that your PVC coated items provide ultimate protection for your needs.